system description

Design

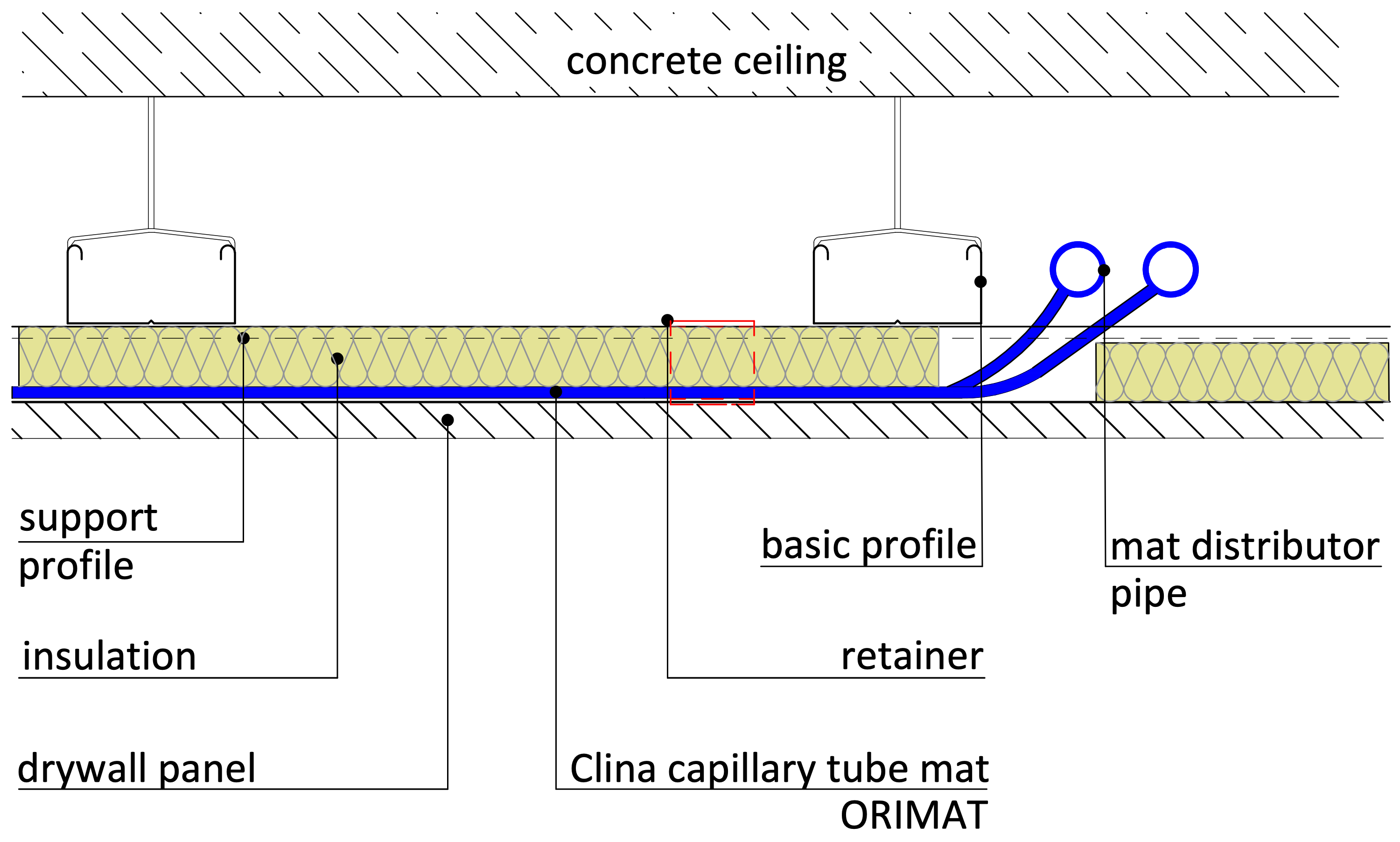

The capillary tube mats and insulation are placed on a suspended drywall ceiling. On the visible side, there is a closed, jointless ceiling for the removal or supply of sensitive heat loads. The water circulates noiselessly in the capillary tube mats and regulates the room temperature to a large extent via radiation, partly also by convection.

Capillary tube mat

The Clina capillary tube mat ORIMAT S 10 is recommended for this design.

Length & width

The capillary tube mats are custom-made in terms of length and width. At the construction site, the mat distributor pipes are connected to one another by heating element socket welding. This is a secure,

non-detachable connection.

Hydraulic connection

The capillary tube mats, connected to a hydraulic circuit, are connected to the supply and return lines, which are located in the void of the suspended ceiling, by heating element socket welding. Alternatively, the connection can be made using a proven push-lock system with flexible hoses.

The ceiling void can of course be used for further installations.

Mounting

The capillary tube mats are fixed between the profiles of a suspended drywall ceiling with retaining brackets or retaining clips.

Drywall panels

Any type of drywall panels can be used - whether unperforated or perforated ceiling. The installation height, ceiling design and heating and cooling capacities vary accordingly.

Lamps & Ventilation

Larger openings must be taken into account in the planning phase.

Up to approx. 100 mm, openings can also be made during the construction phase by simply pulling the capillary tubes apart.

Regulation

The system can be regulated room-by-room.

Fields of application

Suitable for all types of buildings, such as office buildings, residential buildings, hotels, etc., whether new construction or renovation.

structure

View of a ceiling section: jointless drywall ceiling with capillary tube mat

The mat distributor pipes of the capillary tube mats are connected to each other by heating element socket welding.

The capillary tube mats, connected to a hydraulic circuit, are connected to the supply and return lines by heating element socket welding, which are located in the void of the suspended ceiling. Alternatively, the connection can be made using a proven push-lock system with flexible hoses.

Mat distributor pipes and supply lines are located in the hollow space of the suspended ceiling.

To close the ceiling, the capillary tube mats are rolled out step by step, insulation boards are placed on top and drywall panels are screwed on from below.

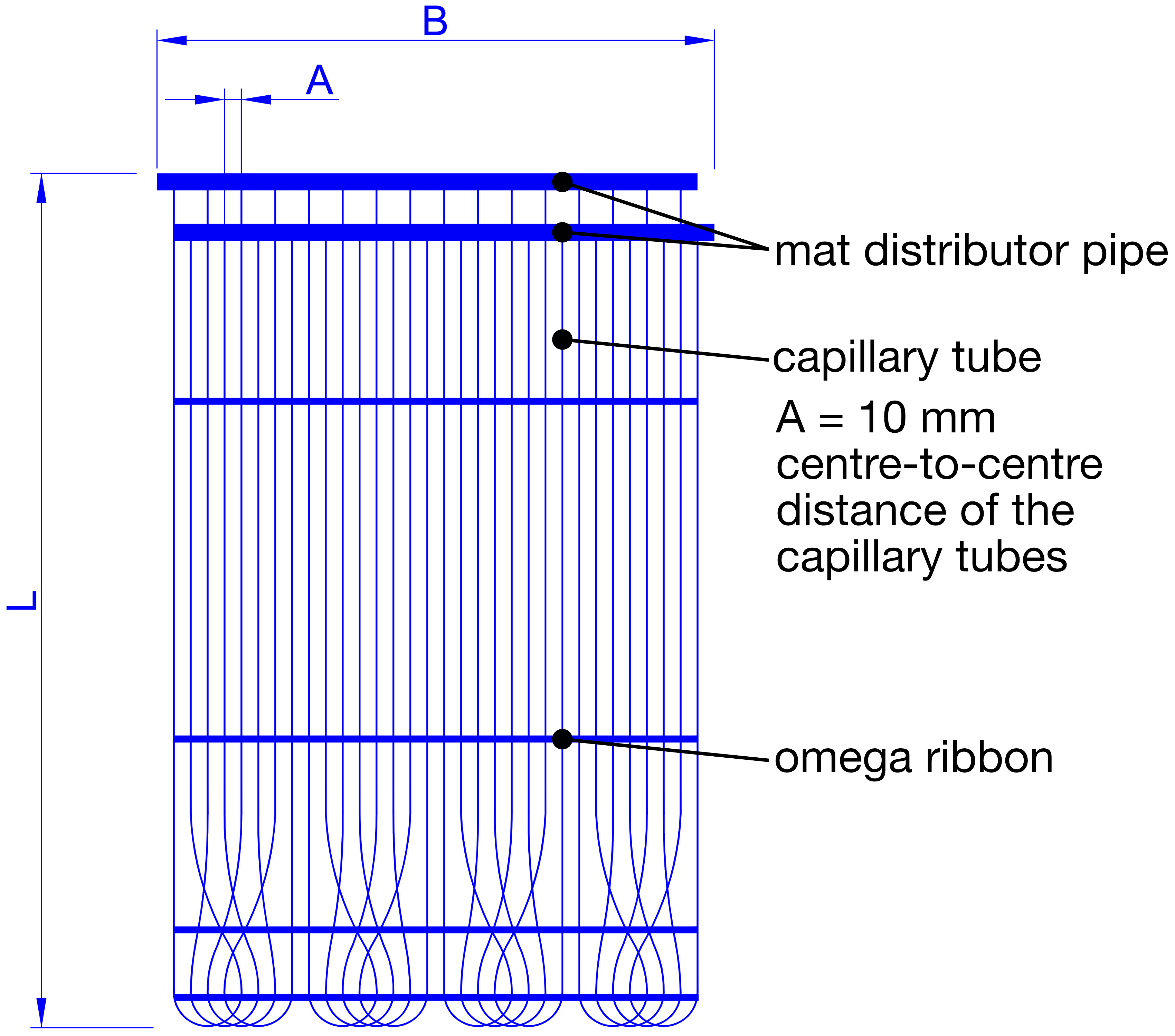

recommended capillary tube mat

The ORIMAT S 10 consists of 2 round mat distributor pipes (20 x 2,0 mm) and capillary tubes (3,4 x 0,55 mm).

The constant distance between the capillary tubes (centre-to-centre distance) is 10 mm and is guaranteed by the omega ribbons.

ORIMAT S 10

advantages

Cooling and heating with one system

In most buildings, the heat requirement to be covered is so low due to the well-insulated building envelope, that capillary tube mats invisibly integrated into the ceiling not only provide excellent cooling in the summer, but can also be used to heat very comfortably and energy-efficient in the cold season.

Unrestricted acoustics

The acoustic properties of the perforated drywall panels are retained in accordance with the manufacturer‘s specifications.

Good price/performance ratio

An existing or already planned drywall ceiling can be activated without additional expenses.

Low installation height

To install Clina capillary tube mats and the supply lines, the ceiling only has to be suspended approx. 10 cm.

Easy installation

Simple, fast and clean mounting, with the works being decoupled, which allows for an unproblematic contractual and temporal separation of the sub-works of heating/cooling and dry construction. The capillary tube mats can be connected very easily to the supply line in the ceiling void.

Individual room control

The temperature can be regulated room-by-room.

values

|

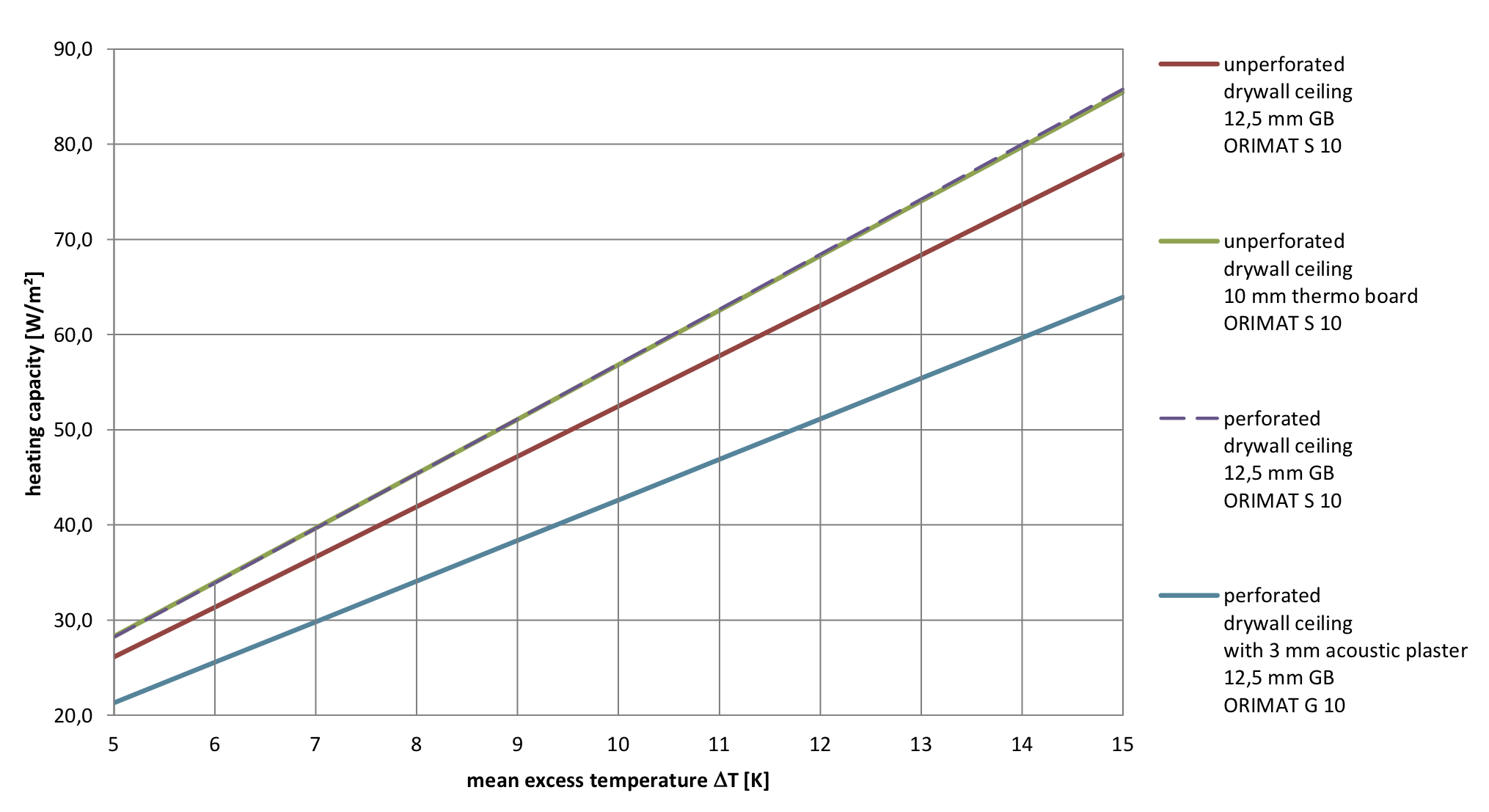

HEATING CAPACITY according to DIN EN 14037/2 |

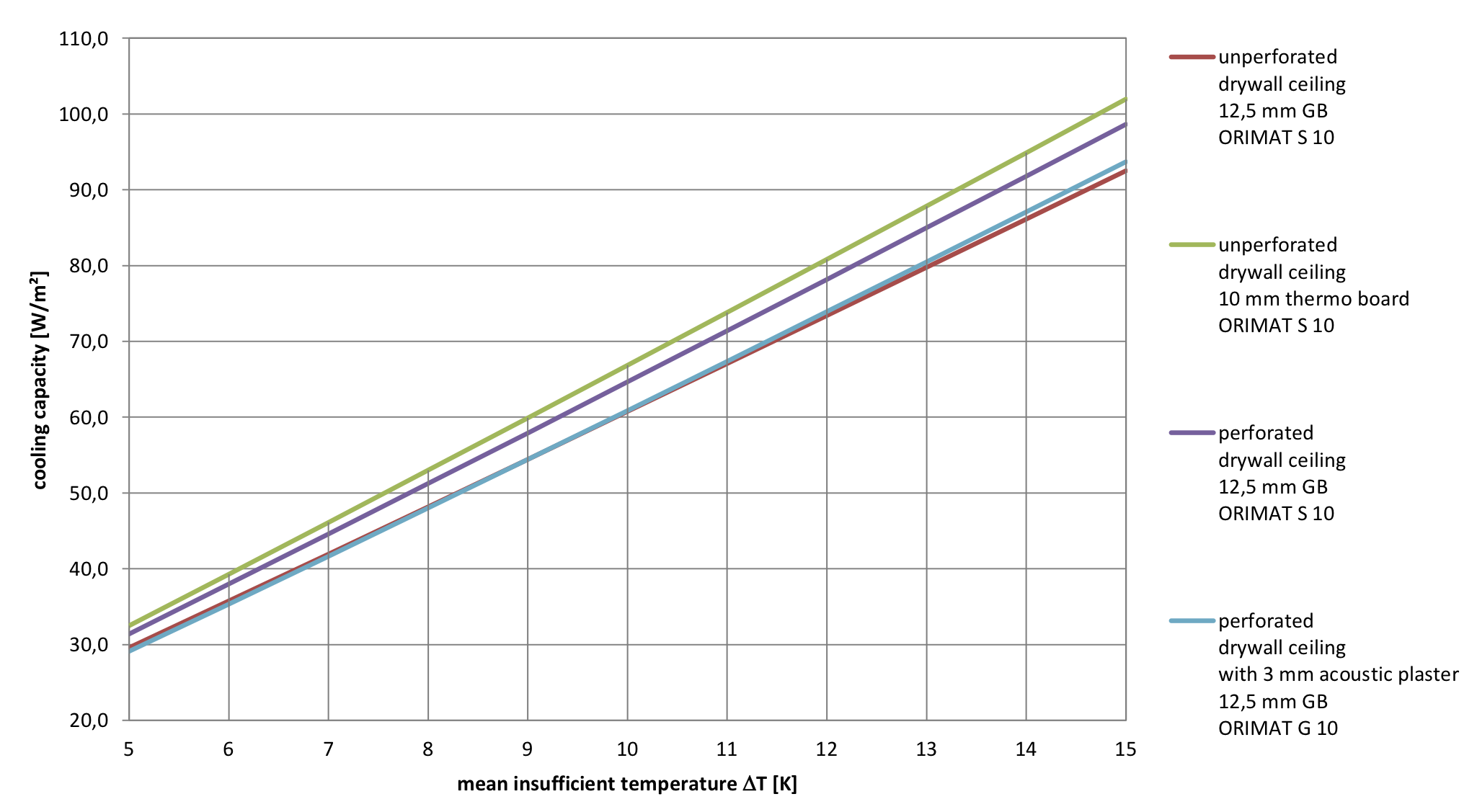

COOLING CAPACITY according to DIN EN 14240 |

ACOUSTICS (only applies to perforated version) |

|

up to 85,8 W/m² (unperforated up to 85,8 W/m² (perforated |

up to 66,9 W/m² (unperforated up to 64,9 W/m² (perforated |

weighted sound absorption coefficient up to 𝝰W = 0,7 (Class C) |

|

INSTALLATION HEIGHT: suspension height |

SYSTEM WEIGHT: |

PRESSURE STAGE: PN 10 |

performance diagrams

SPECIFIC COOLING CAPACITY ACC. TO DIN 4715 / DIN EN 14240

SPECIFIC HEATING CAPACITY ACC. TO DIN 4715 / DIN EN 14240 / 14037-5 (DRAFT)