inspired by nature

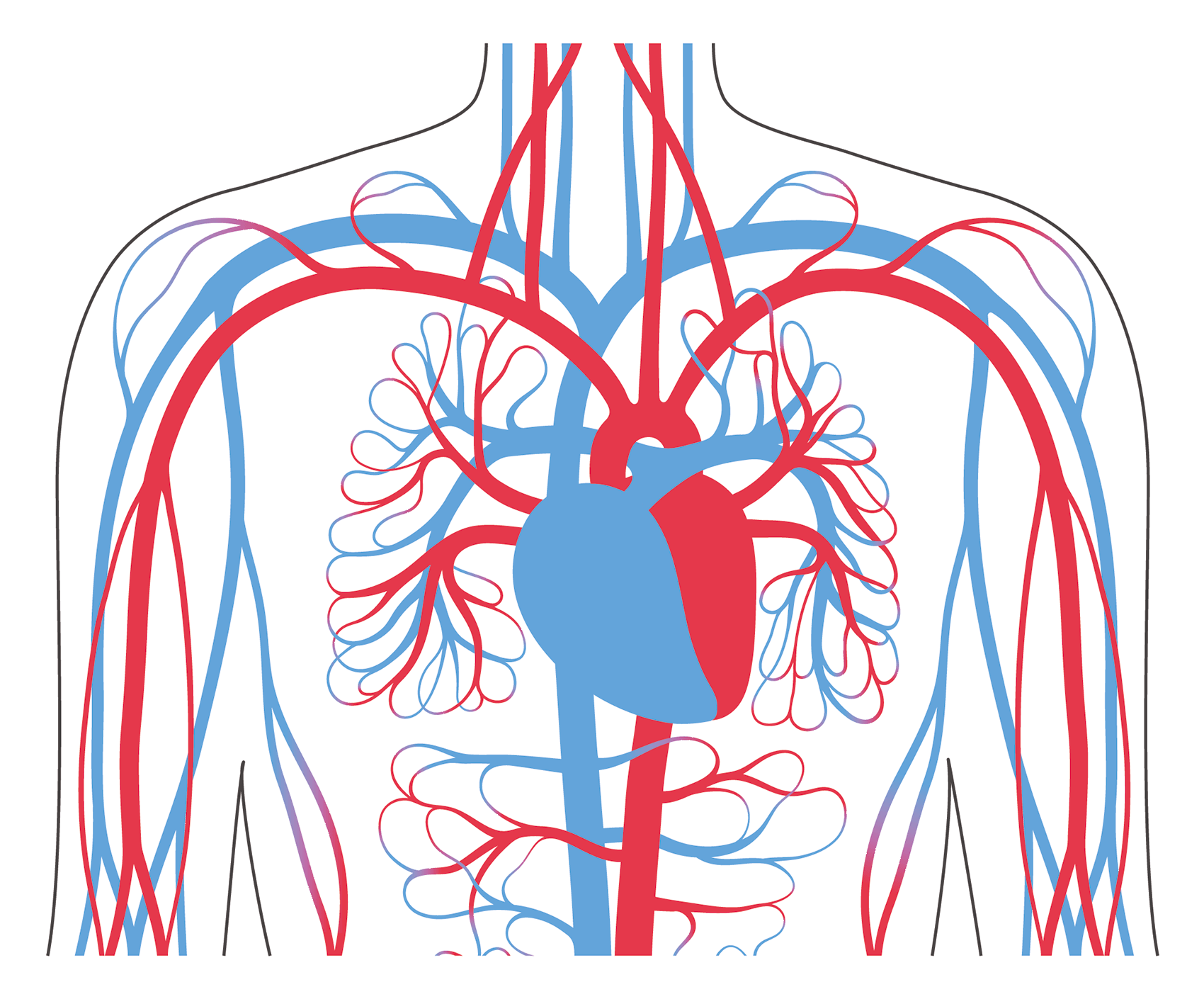

A capillary tube mat is similar to the human blood circulation:

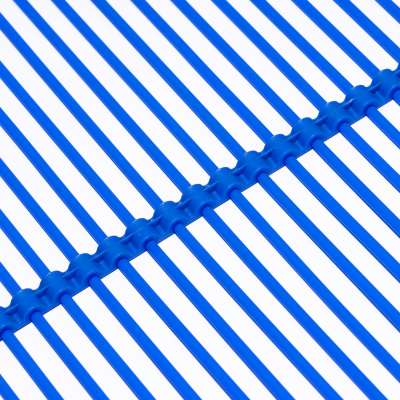

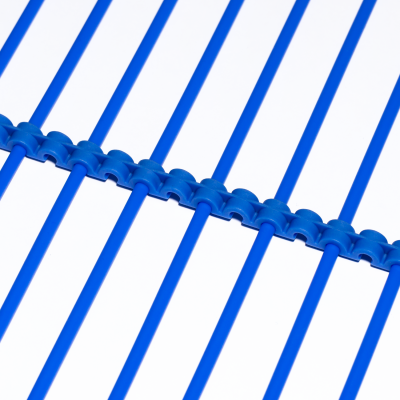

The total mass flow is divided into parallel fluid flows in the capillaries. The flow velocity in the arteries and in the capillary tubes is around 0,05 m/s up to 0,2 m/s. For cooling or heating spaces cold or warm water flows through the capillary tubes with an outer diameter of 3,4 or 4,3 mm.

| capillary system in the human blood circulation |

capillary tube system in the heating and cooling circuit |

|---|---|

© pikovit - stock.adobe.com |

|

Capillary tube mats from Clina

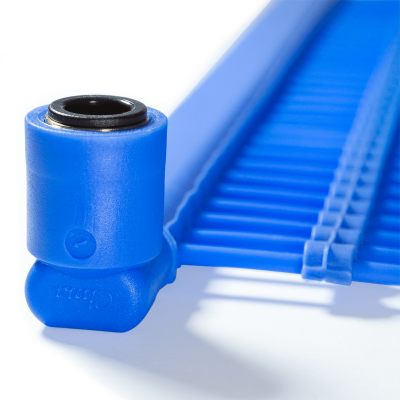

For the production of Clina capillary tube mats (CTM), pipes, supply + return lines we use only high-quality Polypropylen-Random-Copolymerisat (PP-R), DIN EN ISO 19069-1.

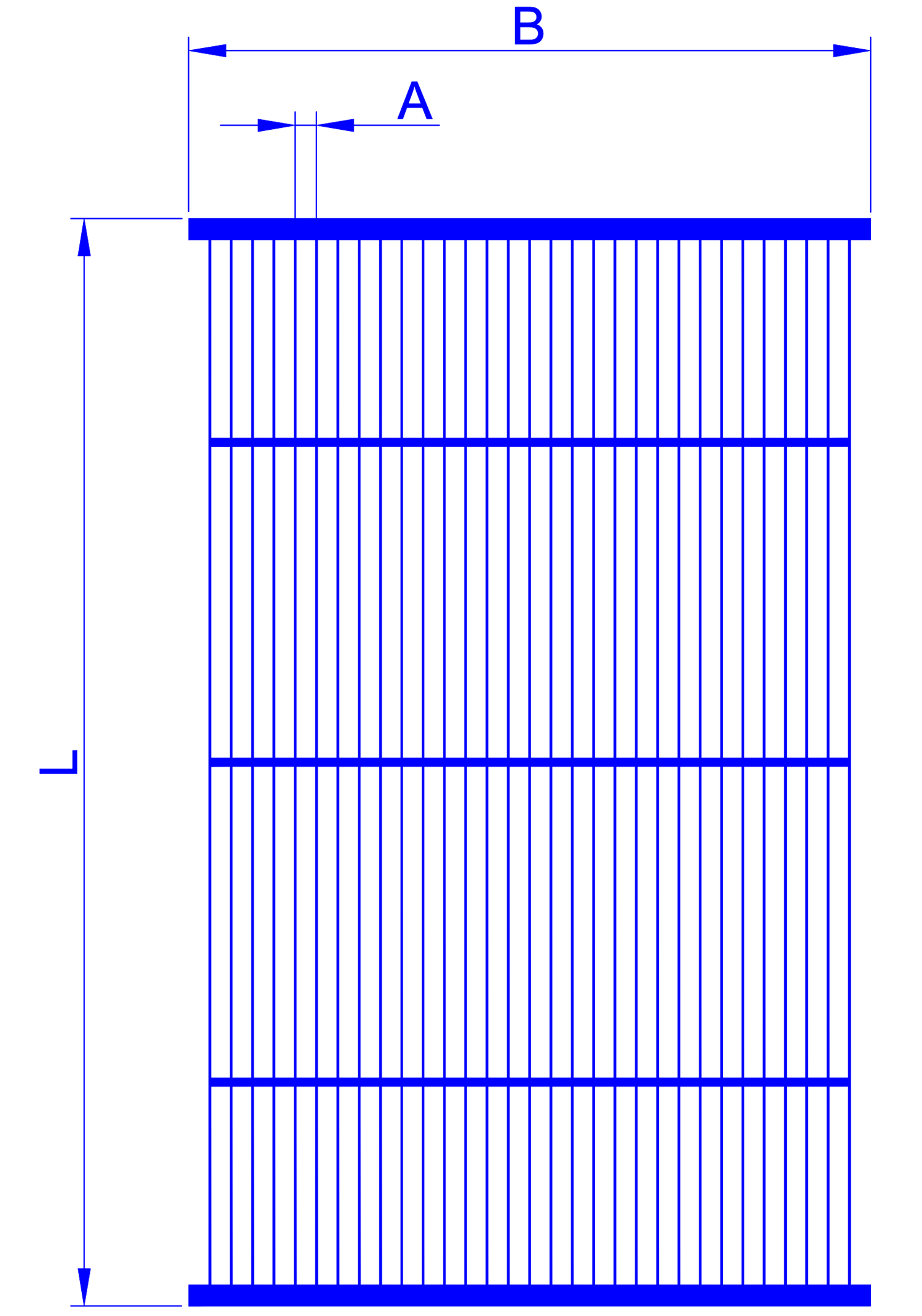

In order to provide an ideal capillary tube mat for each application, the Clina team in Berlin has been researching and developing since the 1990s. The currently available capillary tube mats differ in terms of diameter & distance of the capillary tubes, mat shape, diameter and position of the mat distributor pipes, as well as in terms of the carrier material. Moreover various conncections are also available.

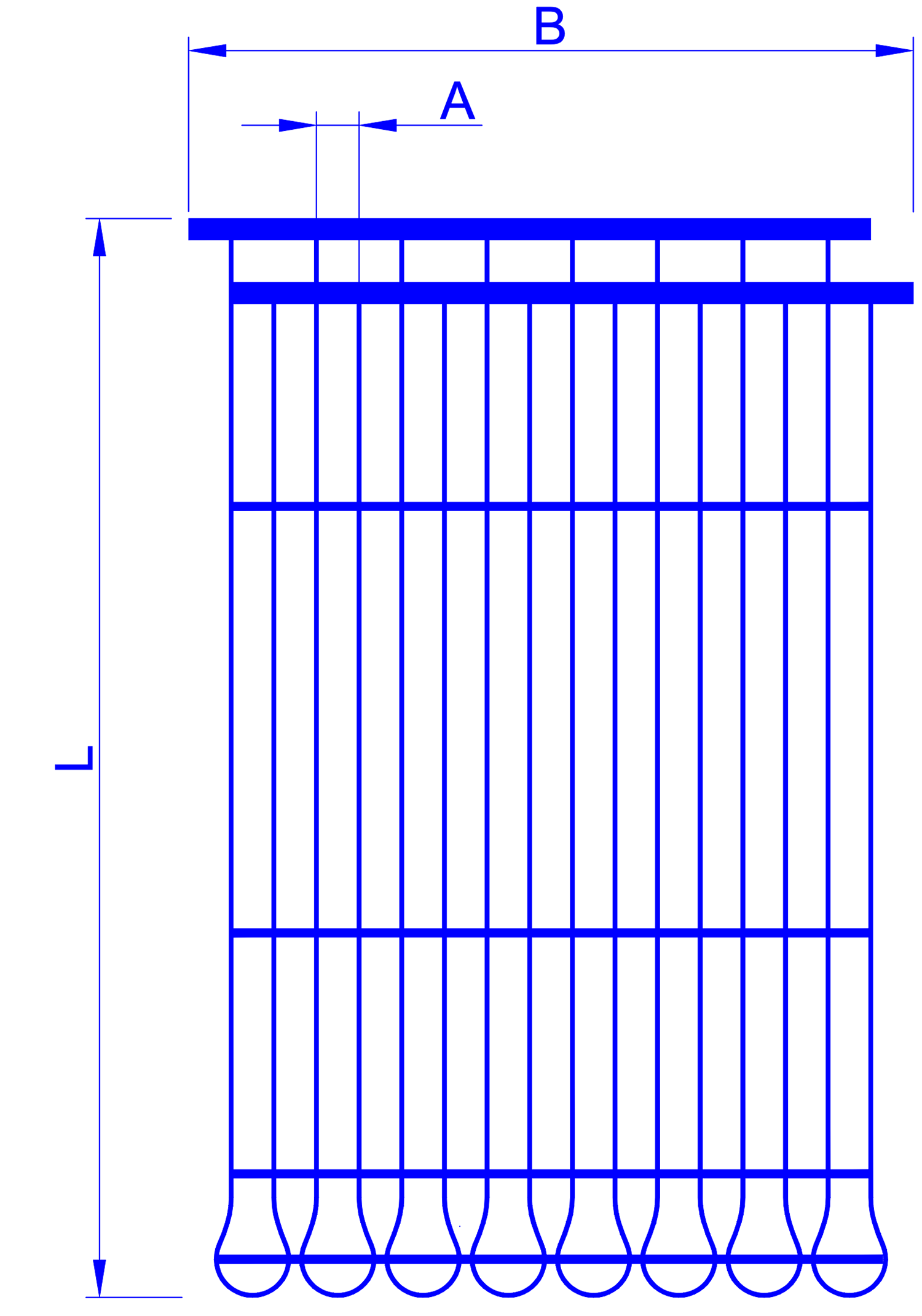

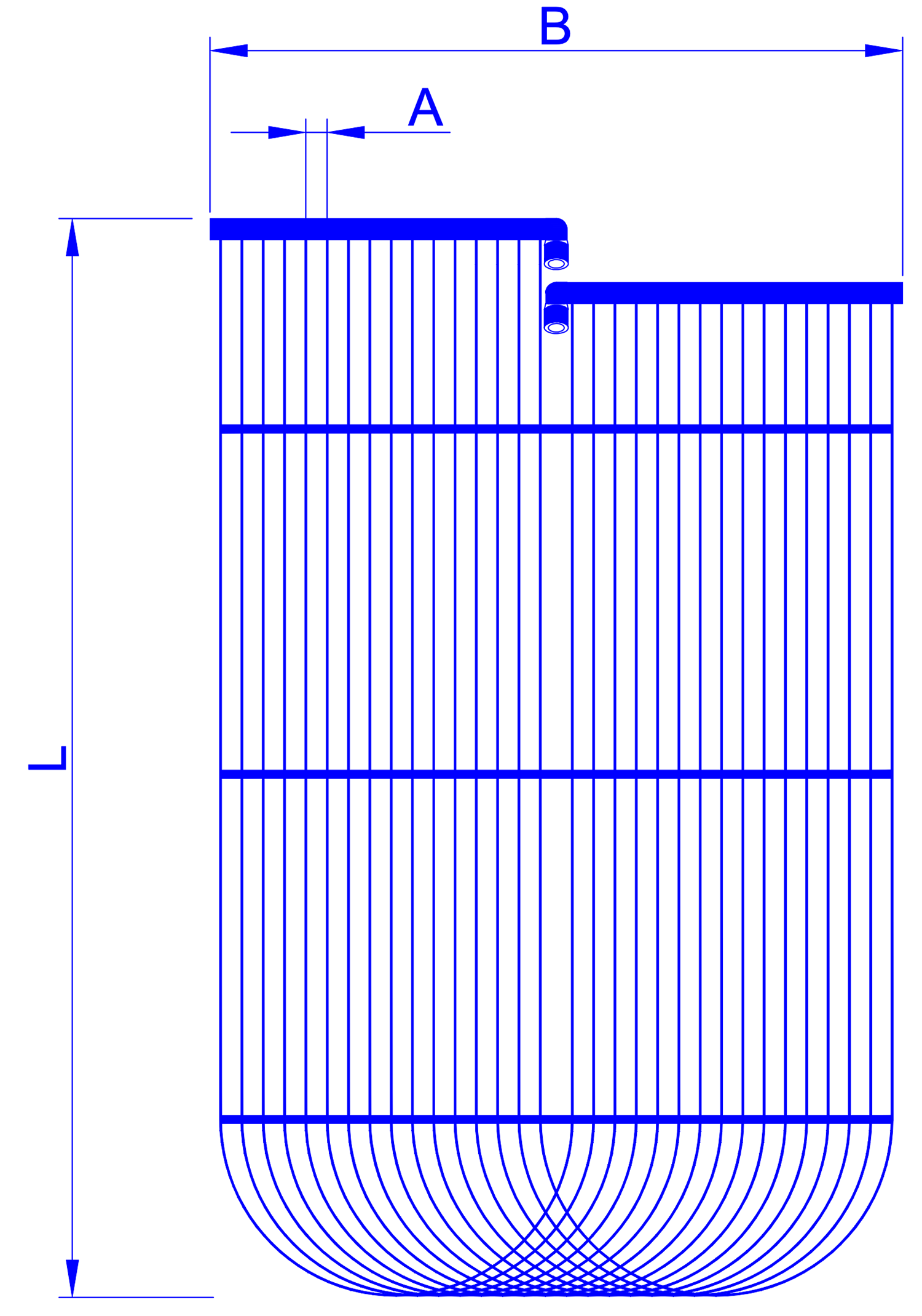

basic shapes of Clina capillary tube mats

G - Mat |

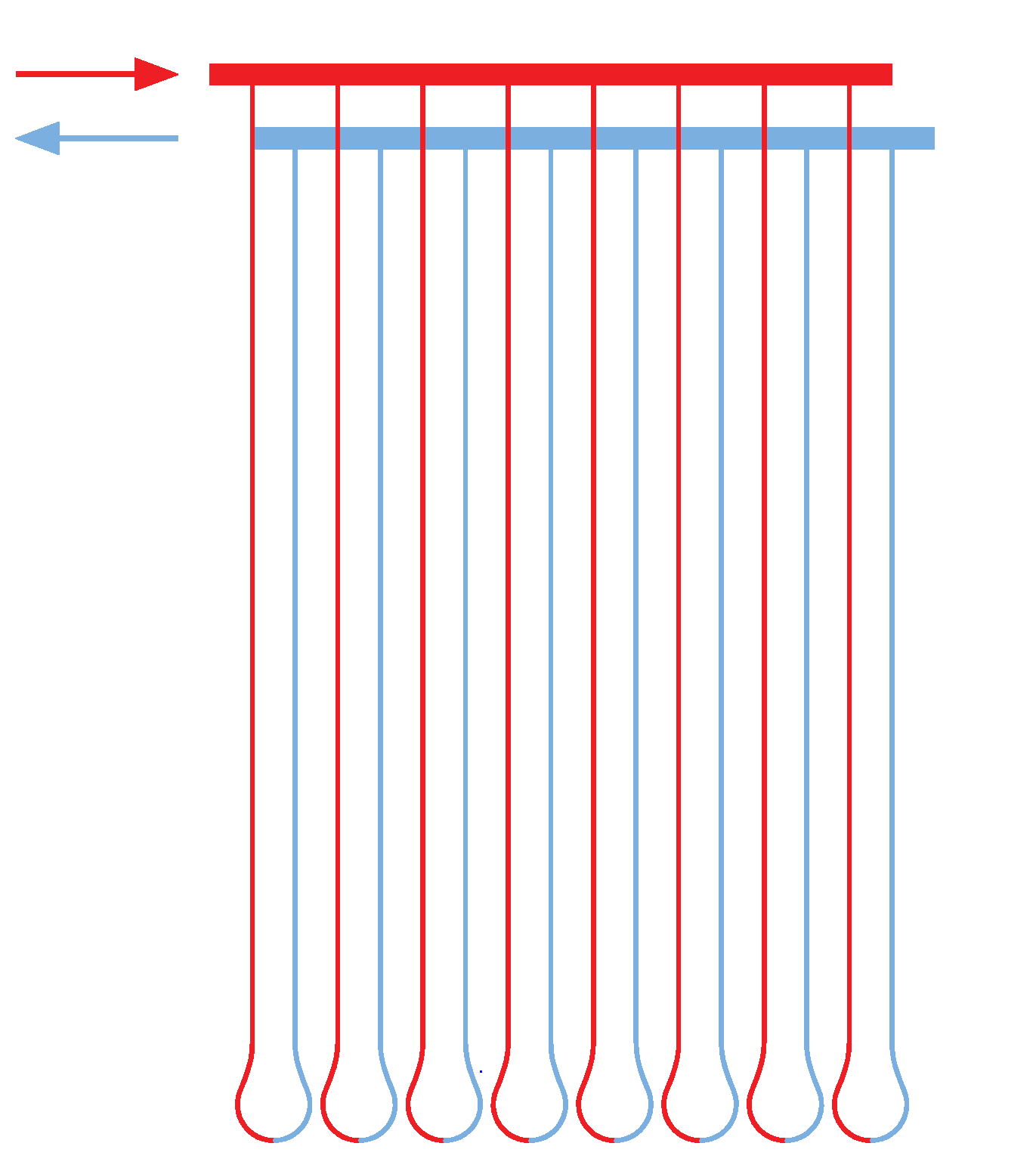

S - Mat |

U - Mat |

|---|---|---|

|

|

|

| G = STRAIGHT MAT (GERMAN: GERADE MATTE) |

S = MAT WITH LOOPS (GERMAN: MATTE MIT SCHLAUFEN) |

U = MAT TURNED ROUND (GERMAN: UMGELENKTE MATTE) |

basic types of Clina capillary tube mats

advantages compared to the single-pipe system

The capillary tube mats with a parallel flow have the following excellent characteristics:

- low pressure loss (cost reduction of circulating pump)

- high dynamics (short reaction times of just a few minutes)

- large heat exchange surfaces due to small distances between the capillary tubes (even heat distribution on the surfaces)

- small differences between system and ambient temperature (energy saving, high efficiency)

These characteristics ensure, among other things, a room temperature control with utmost comfort & well-being.

Further advantages:

- high heating and cooling capacities

- light weight

- very flexible (e.g. suitable for curved surfaces)

Field of application

Clina capillary tube systems are preferred wherever, the objectives of a comfortable indoor climate, low operating and maintenance costs and environmentally friendly operation have to be met.

In addition, architectural reasons such as surface properties, space requirements and flexibility often play an important role. Capillary tube mats are used in new buildings and refurbishment of various types of buildings.

Capillary tube mats are used as heating and cooling systems in room surfaces or in room elements like the GRAVIMAT for heating, cooling and dehumidification as well as for energy recovery & energy storage. Capillary tube mats have long been used as ground collectors and in pilot projects as façade absorbers and in latent heat storages.

(WWW.PROJEKTWEBSITE.DE)

(Andreas Hauer, Stefan Hiebler, Manfred Reuß, Wärmespeicher, BINE-Fachbuch, 5. Aufl., 2013)

Production

All Clina capillary tube mats are made in Germany from high quality polypropylene. Constantly further developed production machines and a unique welding technology for connecting the capillary tube with the mat distributor pipes ensure a very high quality standard and allow a long-term guarantee. Every single product is subjected to an intensive quality control, before it leaves the company.

handling of oxygen diffusion

Oxygen diffuses through polypropylene (PP), i.e. it gets through the wall (walling) into the pipe. Until the saturation limit is reached, oxygen, not to be confused with air, gets into the system. Since oxygen-containing water leads to corrosion, it is essential to run the system by using corrosion-resistant materials. If heat generators or cold generators are not corrosion-resistant, a system separation using a heat exchanger is recommended to form a secondary circuit.

It is a common misconception that diffusion-tight pipelines prevent oxygen from entering the system. Through valves and pipe fittings always gets oxygen into every system - which sooner or later leads to corrosion and siltation.

It is therefore state of the art to carry out a material separation by means of a heat exchanger between the primary and secondary circuit. Only corrosion-resistant components are to be used within the secondary circuit (capillary tube system).

If you have any questions on this topic, the Clina staff will be happy to advise you by phone.

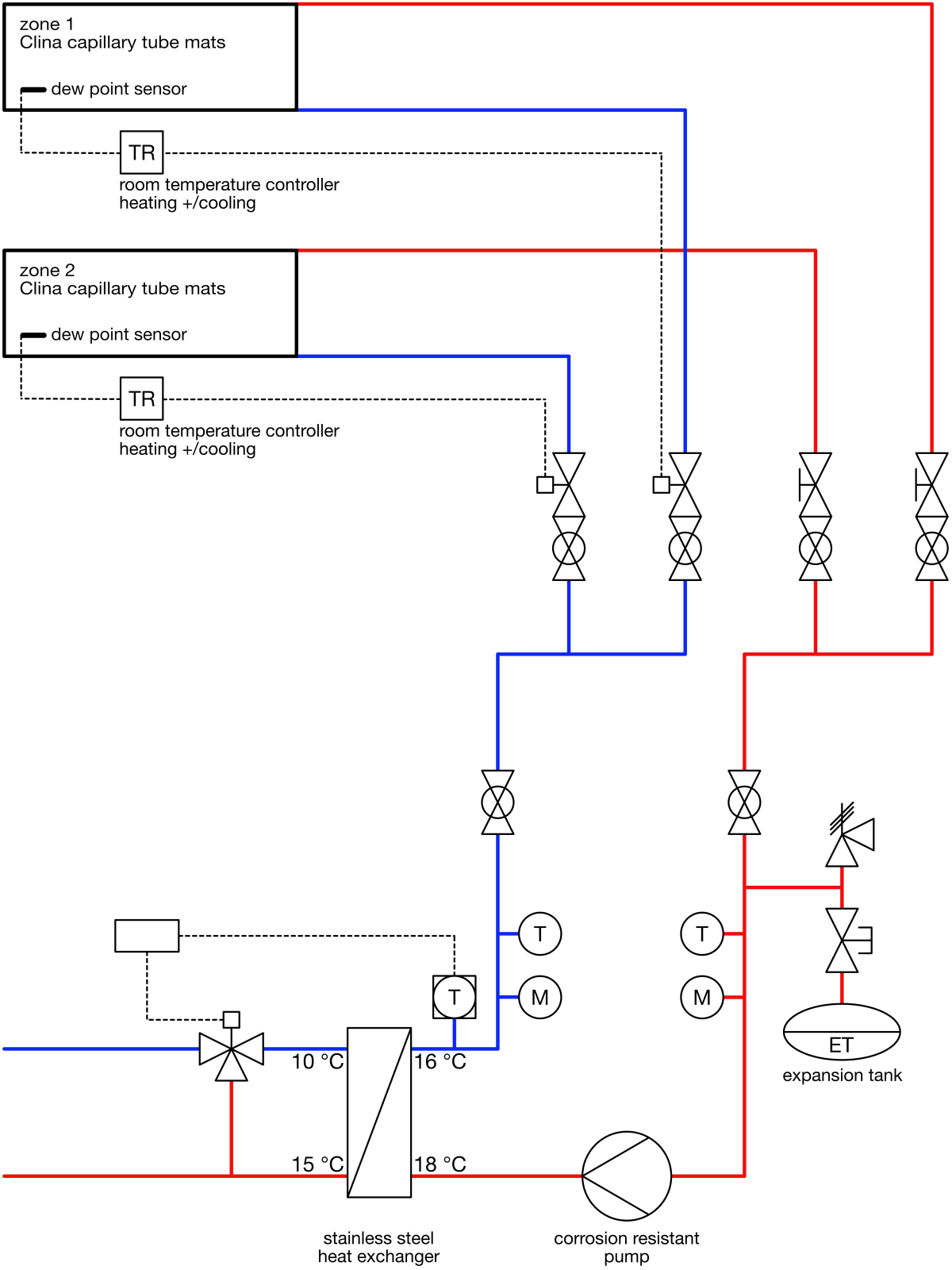

system and control schematic

Principle sketch - Clina capillary tube system cooling