dew point / condensation / condensation water

How is the reaching of the dew point, condensation or condensation water on the cooling surfaces avoided at high heat with high humidity (e.g. 95%)?

There are several possibilities:

- Sliding increase of the cooling water temperature depending on the humidity (enthalpy)

- Switching off the cooling by dew point sensor

A dew point sensor is installed on each cooling circuit. It changes its electrical resistance depending on the air humidity. If there is a dew point risk, the corresponding cooling circuit is switched off (actuator closed). When the dew point risk no longer exists, this safety switch-off is automatically cancelled again.

- Dehumidification of the room air with an additional ventilation system

Cooling ceiling or wall cooling reduces the necessary size of the ventilation system and requires 2 to 3 times less air exchange compared to the solution without surface cooling.

- Installation of the convector GRAVIMAT

The GRAVIMAT offers besides the heating and cooling function also the possibility of dehumidification. The warm air enters the convector, cools down, moisture or condensate condenses on the capillary tubes, and is collected in a condensate tray and removed.

MORE INFORMATION

room temperature

What room temperature can be reached when heating/cooling?

The room temperature that can be achieved depends mainly on the following conditions:

a) Heating capacity/Cooling capacity of the activated surface, depending on:

- Cooling with a temperature falling below the dew point level permissible or not

- Type of construction (e.g. ceiling, wall or floor and their total thermal resistance/system characteristics and the installation situation of the system

- Installed active surface

- Temperature difference between the heating/cooling medium (in the capillary tube mats) and the room air temperature

b) Total sum of the heating load/cooling load (external and internal loads), depending on:

- Number of persons

- Number and heat output of additional heat sources

- Insulation of the buildings

- Size and tightness of windows

- Air exchange rate

The heating /cooling capacities achievable for the different types of heating/cooling surfaces are shown in special performance diagrams. Whether the heating/cooling capacity is sufficient for the specific application, or whether additional measures are required, can only be assessed after determining the heating/cooling load

system separation

Is a system separation by heat exchanger necessary?

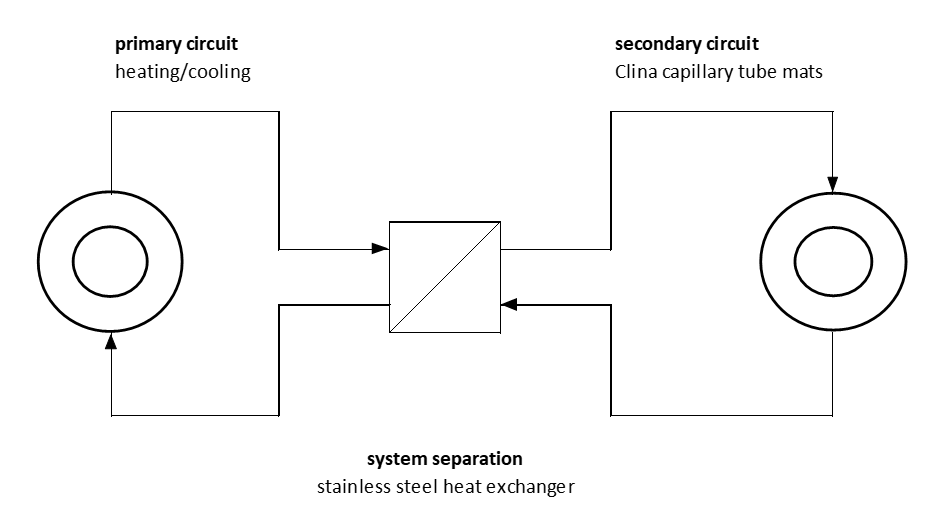

Clina capillary tube mats are made of polypropylene. Polypropylene is not diffusion-tight against oxygen. As a result, small quantities of oxygen enter the closed circuit of the Clina system through the tube walls of the capillary tubes until the water is saturated. In order to prevent corrosion damage, a system separation is therefore carried out between the chiller/heat generator and the heating/cooling circuit (capillary tube mats) using stainless steel heat exchangers. All components (e.g. circulation pump, expansion tank, fittings, pipes, etc.) used between the heat exchanger and heating/cooling circuit, in the so-called "secondary circuit", must be made of corrosion-resistant materials. Provided that they are installed correctly, the formation of corrosion products and the resulting "silting up" of the system is thus definitely ruled out (see figure).

calicification

Can the system calcify?

No. Experience has shown that calcification only occurs at temperatures around 60 °C and higher. As the temperature level in the cooling mode is around 10-20 °C, calcification cannot form in the Clina system capillary tube mats.

siltation

Can "siltation" occur in the system?

Siltation is a consequence of corrosion in a heating or cooling system. The exclusive use of corrosion-resistant materials and a Clina system separation via a stainless steel heat exchanger prevents silting up.

max. cooling capacity

What is the maximum cooling capacity to be expected for cooling ceiling, for convector GRAVIMAT?

Cooling ceiling: Room conditions: Troom = 26 °C

Tsystem = 16 °C

Cooling capacity for metal panels: 94 W/m² (29,7 BTU/h ft²)

Cooling capacity for plaster ceilings: 91 W/m² (28,6 BTU/h ft²)

Cooling capacity for acoustic plaster ceilings: 100 W/m² (32,3 BTU/h ft²)

Cooling capacity for gypsum board ceilings: 74 W/m² (23,9 BTU/h ft²)

GRAVIMAT: Room conditions: Troom = 27 °C

Tsystem = 10 °C

height: 2,00 m

width: 1,00 m

Gravity cooling capacity: 1280 W/m (1331 BTU/h ft)

Output with additional ventilation: 4100 W/m (4260 BTU/h ft)

max. heating capacity

What is the maximum heating capacity to be expected when using ceiling heating, wall heating or floor heating?

Depending on whether it is a floor, wall or ceiling surface, certain limit values should not be exceeded for heating, i.e. for surface temperatures, with regard to comfort and for thermal physiological reasons.

For floor heating systems, the maximum surface temperatures and thus heating capacities are defined according to DIN EN 1264. These limit values are 29 °C (100 W/m²) in the occupied zone and 35 °C in peripheral zones (175 W/m²) at a room air temperature of 20 °C and 33 °C in bathrooms with a room temperature of 24 °C (100 W/m²).

For large-area wall heating systems, specific heat outputs of approx. 120 W/m² are permissible in the comfort zone.

In the case of full-surface ceiling activation, a maximum surface temperature of approx. 30 °C should not be exceeded for room heights up to approx. 3 m in the case of ceiling heating systems. This corresponds to approx. 70 W/m² at a room air temperature of 20 °C.

Depending on the installation situation of the capillary tube mats, the system temperatures must be chosen in accordance with the thermal conductivities in order to comply with the limit values.

water

Is there pure water in the capillary tube mats?

In the capillary tube mats there is usually pure, normal water, which runs in a closed circuit, i.e. the system is only filled once, in compliance with VDI 2035, according to which the filling water for hot water heating systems must be softened depending on the size of the system. This should be done in the same way for the capillary tube system regardless of whether it is used as a heating or cooling system.

capillary tube damaged

What happens if a capillary tube is damaged during installation?

When the Clina system installation is complete, a leak test and safety check of the system is carried out. During this test, it is checked whether the Clina system has been correctly installed and is completely pressure-tight. The leak test is first carried out with 3 bar air pressure, then with 10 bar water pressure. If a capillary tube is damaged, it is not a problem and can be repaired without great effort and expense. The capillary tube is separated at the damaged point and both ends of the capillary tube are welded (close). Although there is no longer any energy exchange via this particular capillary tube, it is not noticeable in the overall cooling capacity.

lifetime of the system

How long is the service life of the system?

Under normal operating conditions, the service life is more than 50 years.