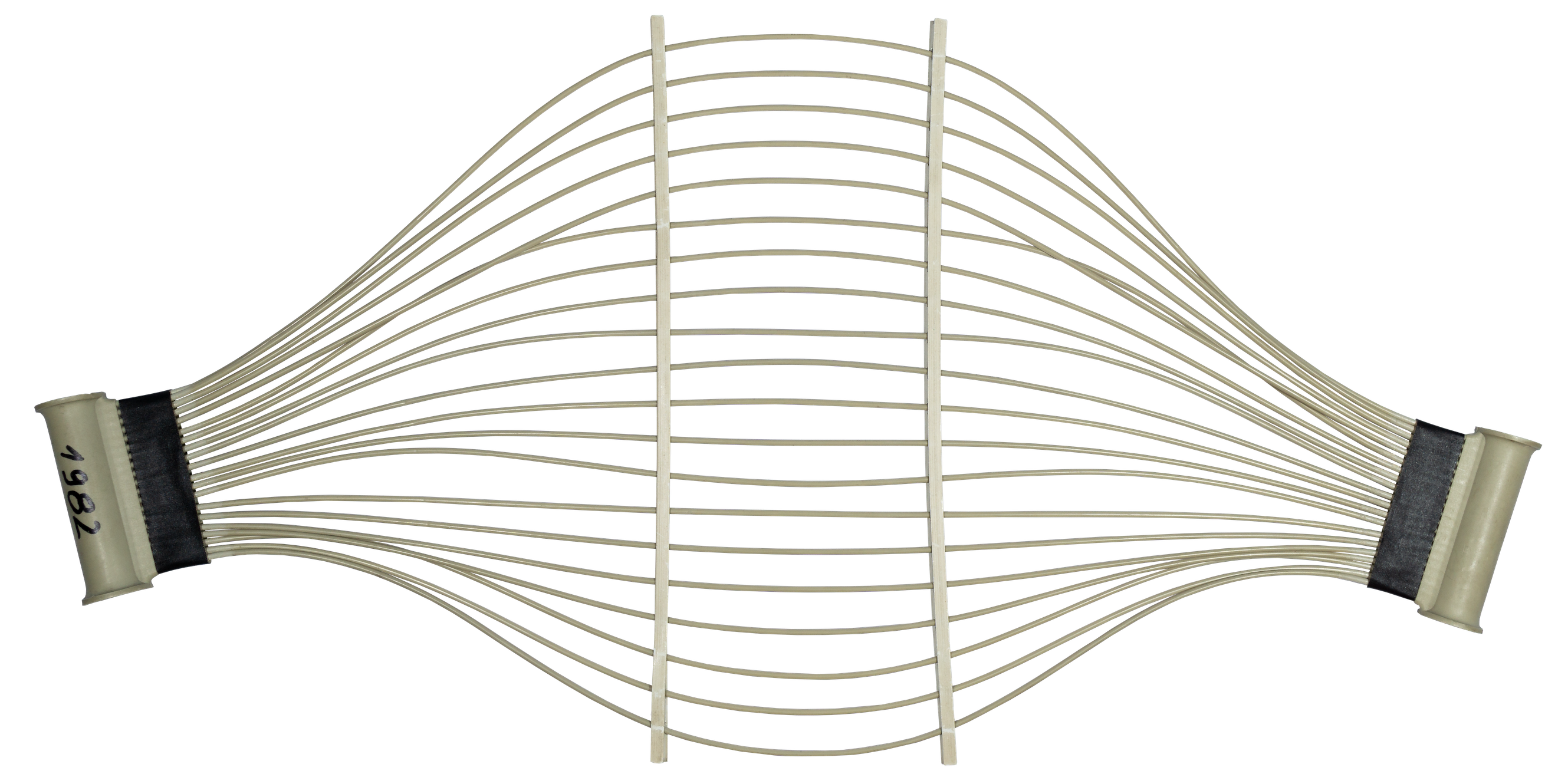

THE FIRST PLASTIC CAPILLARY TUBE MATS

1981/1982

COMPANY FOUNDATION

1994

Dipl.-Ing. Bechir Chahed founds Clina Heiz- und Kühlelemente GmbH together with two partners.

The first commercial Clina capillary tube mat is produced on 21 July 1994.

The mat is named ORIMAT.

PRODUCT LAUNCH ORIMAT

1994

NEW WELDING TECHNOLOGY

1994

Together with a manufacturer of special machines, a new welding technology or welding system has been developed that meets Clina's growing requirements in terms of efficiency and quality:

96 capillaries are welded fully automatically to a distribution pipe.

The reward for the hard work follows in the same year.

GOLD MEDAL

1995

With ORIMAT, Clina wins the gold medal in the category "Innovative Product" at the INTERCLIMA trade fair for energy-efficient building technology in Paris.

REICHSTAG BERLIN

1996

The historic edifice served as the seat of the Reichstag (parliament) in the German Empire as well as in the Weimar Republic and is the seat of the German Bundestag since 1999. It undergoes a reconstruction from 1995-1999 led by architect Norman Foster. In 1996, the offices are equipped with gypsum board ceilings with Clina capillary tube mats laid on top. Clina provides around 7,000 m² of capillary tube mats for the Reichstag. The heating and cooling system based on Clina capillary tube mats is still running.

HEATING, COOLING AND DEHUMIDIFICATION

1997

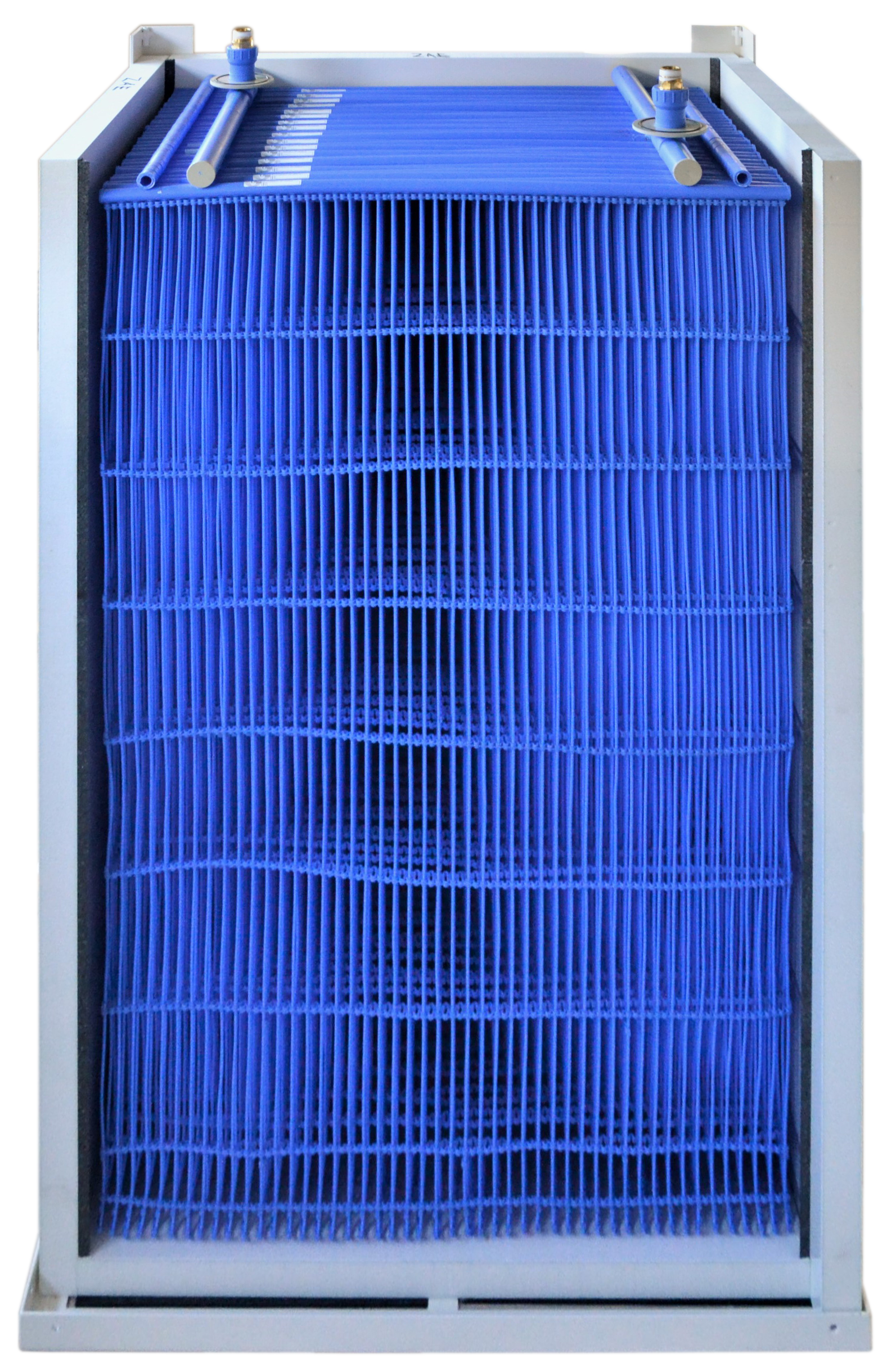

The patented GRAVIMAT as air cooling, air heating and air dehumidifying module is developed. In cases of extreme heat and high humidity, when the classic cooling ceiling would have to be switched off or the output has to be reduced due to the dew point risk, this convector provides a pleasant room climate.

PRODUCT LAUNCH GRAVIMAT

1997

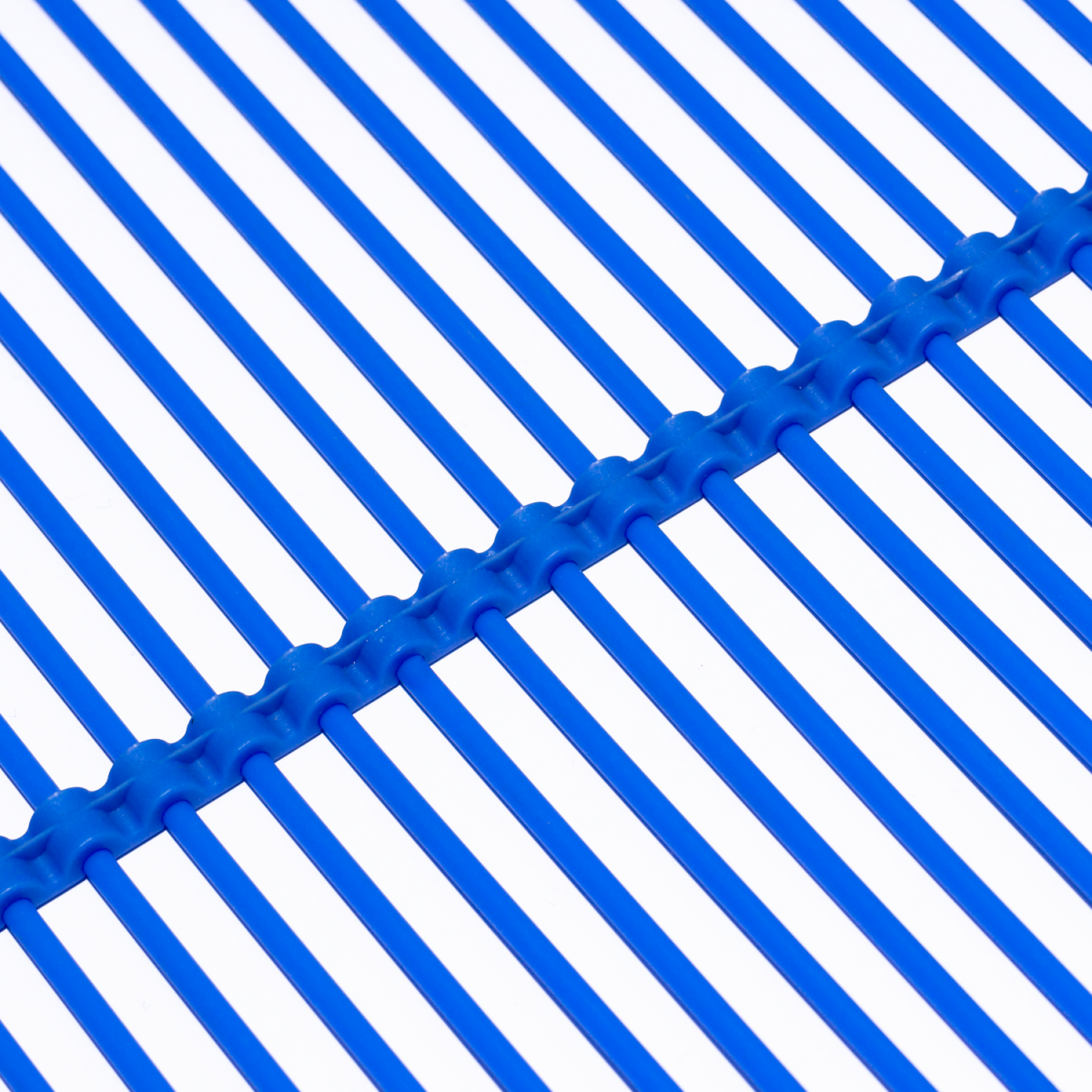

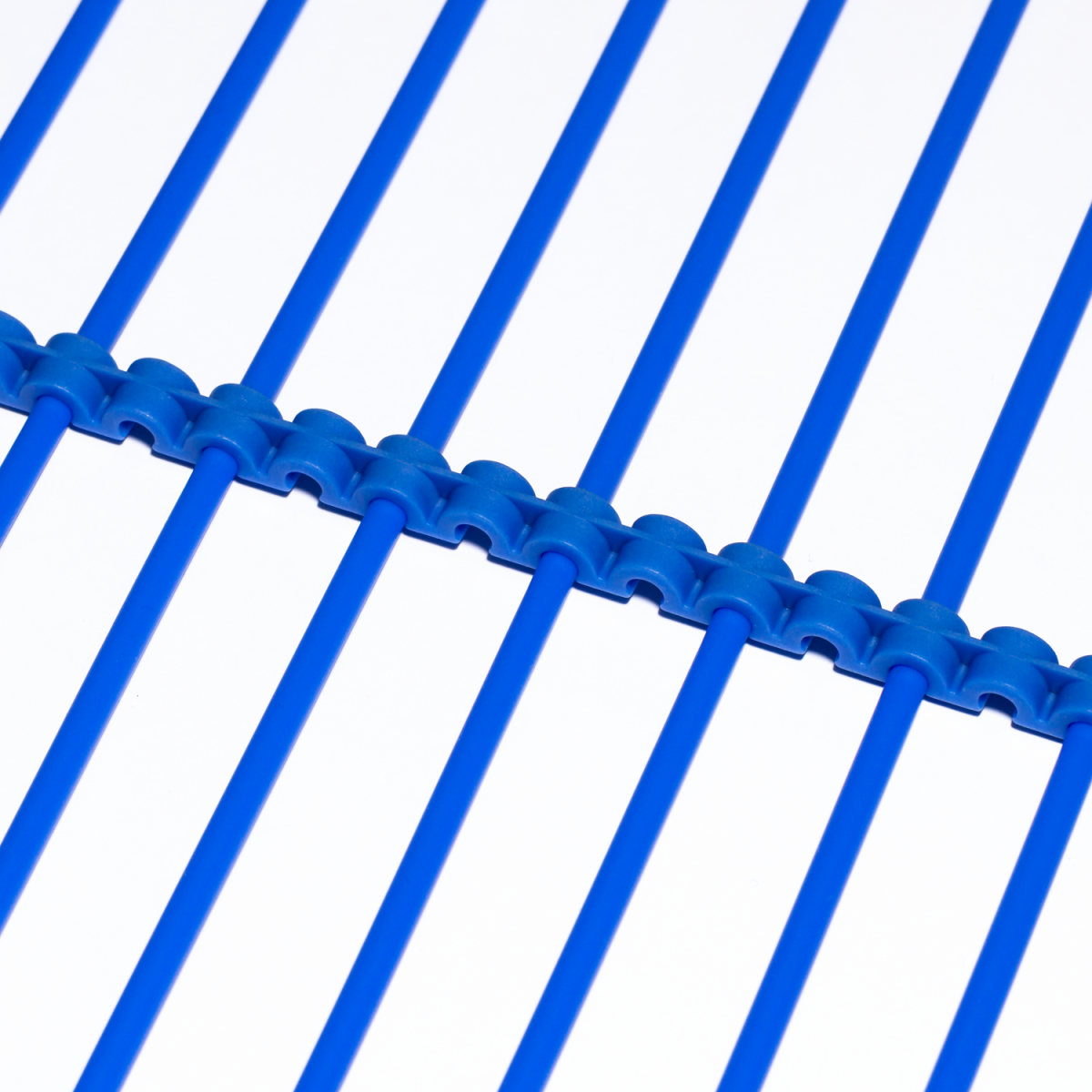

INNOVATION MORE ROBUST CAPILLARY TUBE

1998

The OPTIMAT is especially developed for applications where the capillary tube mat is exposed to increased mechanical or thermal stress. It is designed with a more robust capillary tube, can be vented more easily and has lower pressure losses.

PRODUCT LAUNCH OPTIMAT

1998

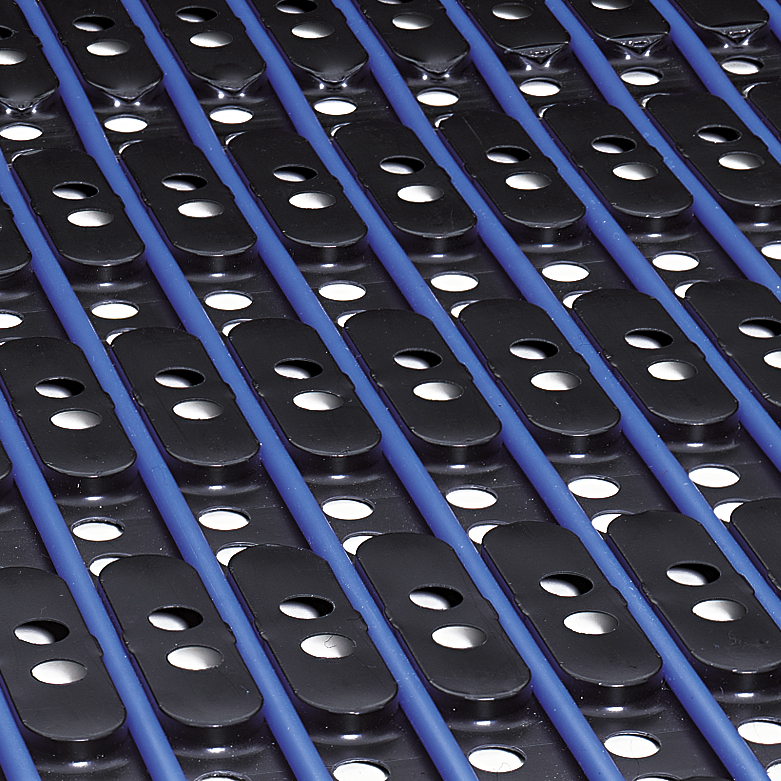

INNOVATION WITH INSERT FOIL

2000

FOLIMAT, the product development of a ready-made capillary tube mat which is clicked into a perforated insert foil. For filling on load-bearing substrates and with a very low installation height, it turns plane surfaces very easily into heating and cooling surfaces.

PRODUCT LAUNCH FOLIMAT

2000

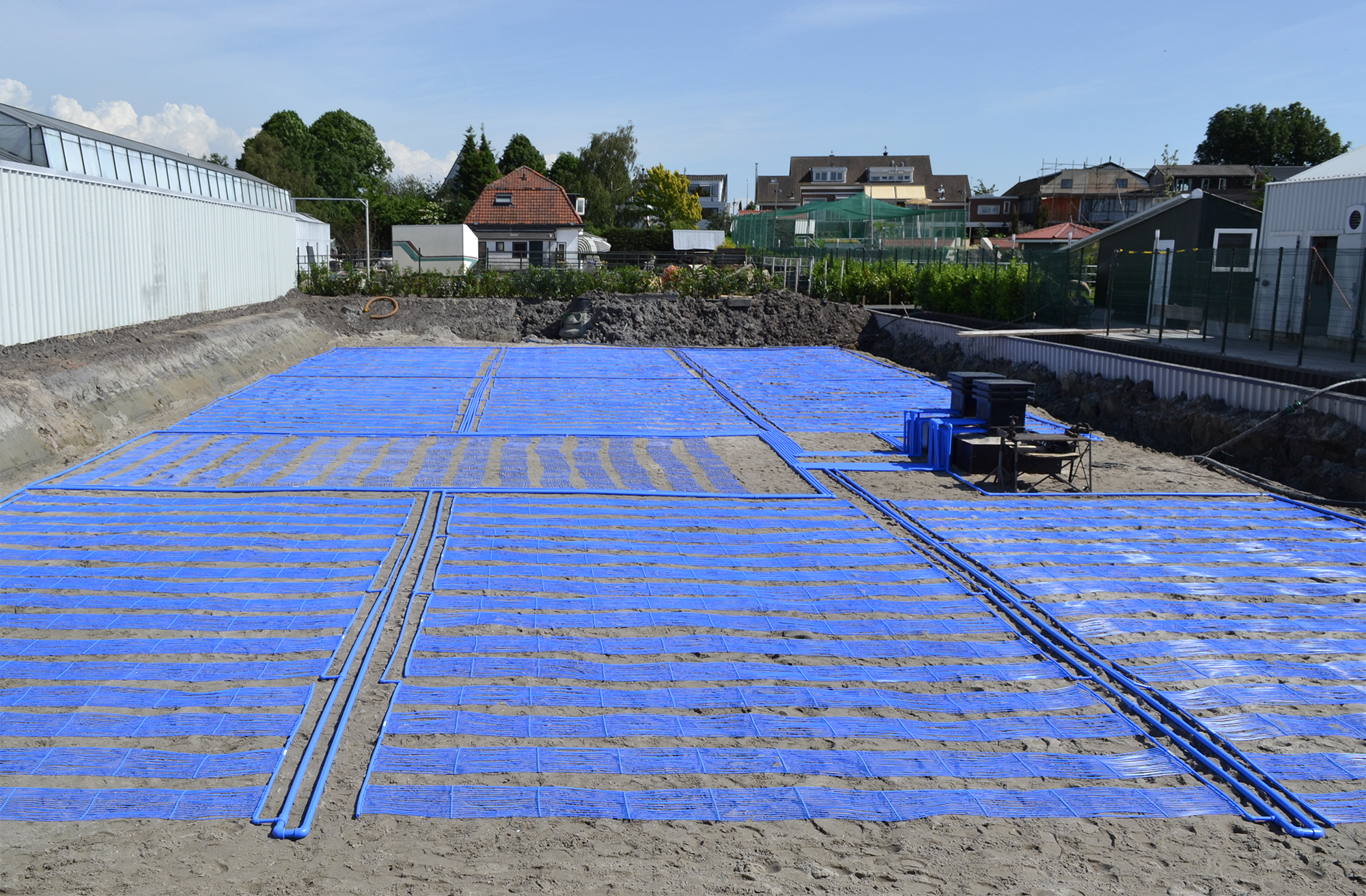

GROUND COLLECTOR

2001

First use of capillary tube mats for the use of environmental energy. In connection with heat pumps, capillary tube mats are installed as horizontal ground collector.

DEVELOPMENT THERMAL ENERGY STORAGE

2006

An innovative latent heat storage system is being developed at the Center for Applied Energy Technology Bavaria (ZAE - Zentrum für angewandte Energietechnik). The heat exchanger matrix of the thermal energy storage consists of Clina capillary tube mats. The phase change material is salt hydrate.

VISIT OF THE FEDERAL ENVIRONMENT MINISTER

2009

In March 2009, Federal Environment Minister Sigmar Gabriel is informed about innovative products and systems from Clina. He is in favour of capillary tube technology and is convinced that Clina capillary tube mats can make a significant contribution to reducing primary energy consumption for heating and cooling buildings.

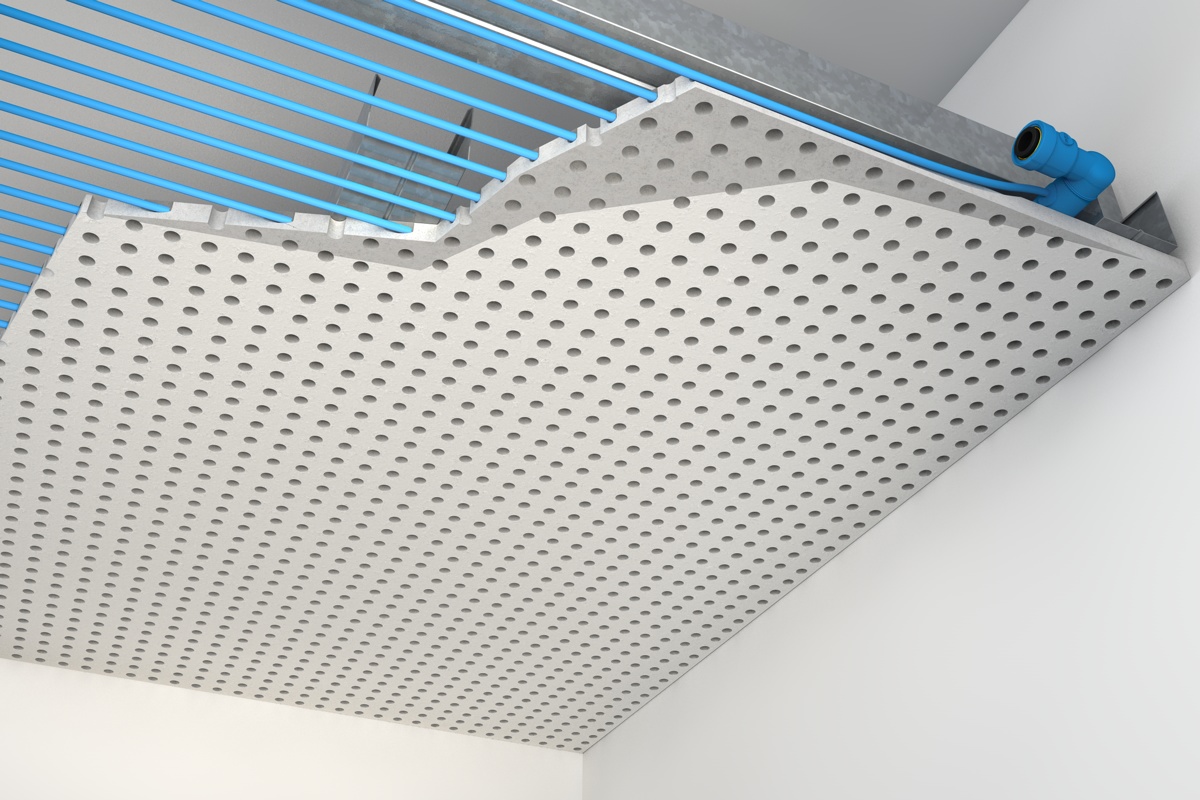

PREFABRICATED MODULES

2014

Development of prefabricated products for ceiling heating and cooling ceiling as well as wall heating and wall cooling. OPTIPANELs consist of a standard gypsum board panel, unperforated (OPTIPANEL 15) or perforated (OPTIPANEL 18) with integrated capillary tube mats.

The OPTIPANELs are fully assembled, ready-to-install modules and are very easy to mount on ceilings or walls.

PRODUCT LAUNCH OPTIPANEL 15 AND 18

2014

FACADE ABSORBER

2014

In various pilot and research projects, Clina capillary tube mats are successfully used as roof absorbers or as facade absorbers, such as in the pilot project "Güterstraße 30, Pforzheim".

NEW PRODUCTION SITE

2018

Production capacity will be significantly increased in March 2018. Clina is investing in state-of-the-art production facilities for capillary tube mats at its second production site in Spreenhagen.

25 YEARS CLINA

2019

Clina celebrates it's 25th company anniversary!

In the meantime, more than four million square meters of capillary tube mats have been produced and applied in all continents of the world in more than 50 countries. Since its foundation in 1994, Clina has supplied custom-made capillary tube mats for over 2000 projects worldwide.

Headquater and production relocation

2020

For about 25 years the production was exclusively located in Berlin. In order to meet the increasing demand, a supplementary production site is opened in Spreenhagen, Brandenburg in 2018. The trend of increasing demand continues, so that Clina generously expands the Brandenburg production site in 2019-2020.

In summer 2020, the entire production is relocated to Spreenhagen and the company headquarters with technical and commercial department moves into new offices in Berlin.