system description

Design

The capillary tube mats, in perforated insert foil, are laid in a 8-10 mm thin levelling compound directly on an existing cement screed or floating screed. Mat distributor pipes and supply lines are located in previously made slots in the existing screed floor. The desired floor covering, such as parquet, tiles or carpet, is applied to the finished subfloor. This flooring material should be suitable for floor heating systems.

The small distance between the capillaries (20 mm), ensures a homogeneous heat distribution across the floor. At low excess temperature, the heat is emitted to a large extent via radiation, partly also via convection.

Capillary tube mat

The Clina capillary tube mat FOLIMAT FSB 20.00 is recommended for this design.

Length & Width

The capillary tube mats are custom-made in length for each room at Clina. The mat type FOLIMAT is available in widths of 300 and 600 mm. On site, the mat distributor pipes are connected by means of heating element socket welding. This is a secure, non-detachable connection.

Hydraulic connection

Mat distributor pipes and supply lines are accommodated in the existing screed. For this purpose, slots are made in the screed and then closed again (with concrete screed or rapid screed). The capillary tube mats, welded together to a hydraulic circuit, are connected to the supply and return lines and to a centrally located manifold.

Mounting

The capillary tube mats are rolled out on the prepared floor and fixed with tile adhesive.

Levelling compound

The levelling compound must be suitable for floor heating systems. A layer thickness of 8-10 mm (incl. capillary tube mats) is sufficient.

Regulation

The system can be regulated room-by-room.

Fields of application

Suitable for all buildings, such as residential buildings, office buildings, hotels etc., especially for renovation, but also for new buildings.

structure

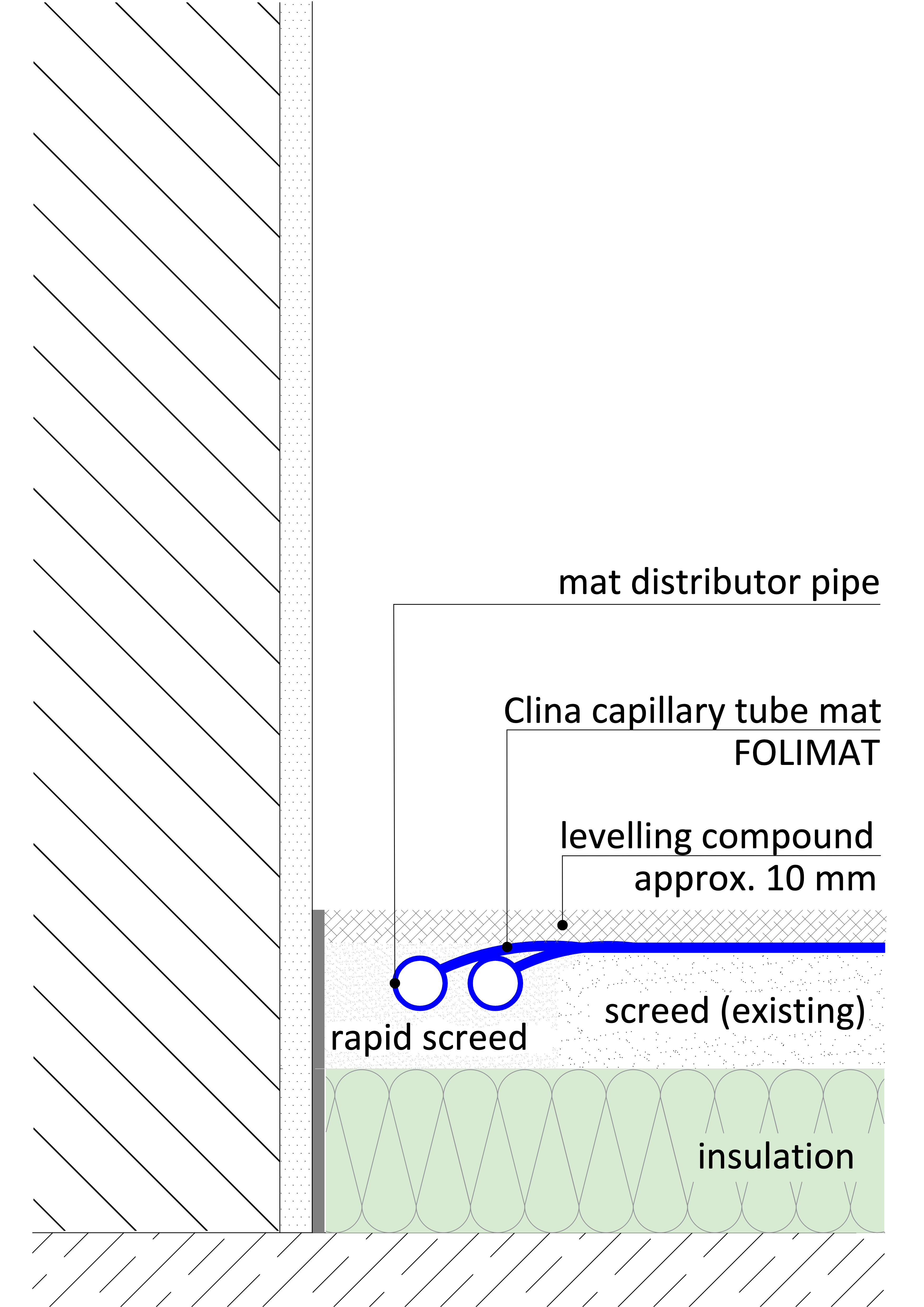

View of a floor section:

capillary tube mat laid on screed

The capillary tube mats, in perforated insert foil, are laid in a 8-10 mm thin levelling compound directly on an existing cement screed or floating screed.

Mat distributor pipes and supply lines are accommodated in the existing screed.

The capillary tube mats are fixed with tile adhesive on the existing screed.

Levelling compound is applied. A layer thickness of 8-10 mm (incl. capillary tube mats) is sufficient.

The desired floor covering, such as parquet, tiles or carpet, is applied to the finished subfloor. This flooring material should be suitable for floor heating systems.

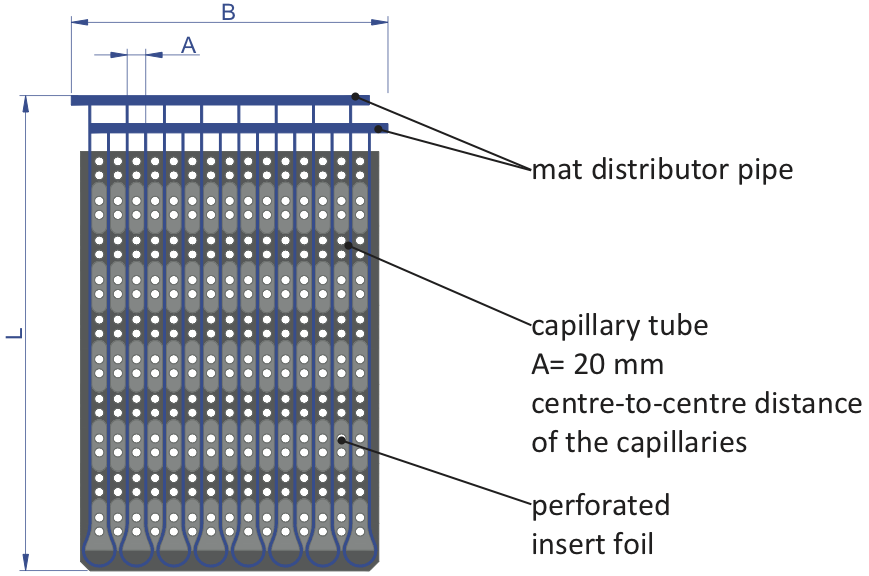

recommended capillary tube mat

The FOLIMAT FSB 20.00 consists of 2 round mat distributor pipes (20 x 2,0 mm) and capillary tubes (4,3 x 0,8 mm) as well as a perforated insert foil.

The capillaries are clicked into the grooves of the insert foil. The constant distance between the capillary tubes (centre-to-centre distance) is 20 mm.

Special features

- high mechanical resilience

- low pressure loss

- good venting

- suitable for thin-layer system

- can be easily glued to various substrates

FOLIMAT FSB 20

advantages

High performance - high dynamics

Thanks to the small distance of the capillary tubes of 20 mm, the floor is heated homogeneously. As a result of this and due to the position of the capillary tube mats close to the surface a high heat output at low system temperatures can be achieved. This results in extremely short warm-up times. Just a few minutes after switching on the heating, you can feel the warmth on the entire floor.

Environmentally friendly and energy efficient

Very low system temperatures and extremely short warm-up times save money and protect the environment.

Low installation height

A layer thickness of 8-10 mm is sufficient. Mat distributor pipes and supply lines are accommodated in the existing screed.

Ideal for renovations

Thin-layer underfloor heating can be installed directly on an existing screed.

Short construction times

Due to the short drying time of the levelling compound, the surface can be walked on and is ready for installation after just a few hours.

Invisible

No bulky radiators, therefore more architectural design options, such as floor-to-ceiling windows. You also have more options when it comes to the interior design.

Ideal for asthmatics and people with dust allergies

Due to the low level of convection you have no stirring up of dust.

Smooth, energy-efficient temperature control

Due to the homogeneous heat distribution it is possible to work with a low system temperature. This has a positive impact on the feeling of comfort and reduces heating energy consumption. The perceived temperature is around approx. 2–3 °C higher than the actual room temperature.

values

|

HEATING CAPACITY |

COOLING CAPACITY |

ACOUSTICS |

|

max. 100 W/m² |

max. 30 W/m² |

depending on floor covering |

|

INSTALLATION HIGHT: 8-10 mm in levelling compound plus floor covering (mat distributor pipes and supply lines in the existing floor) |

SYSTEM WEIGHT: 1020 g/m² plus levelling compound and floor covering |

PRESSURE STAGE: |

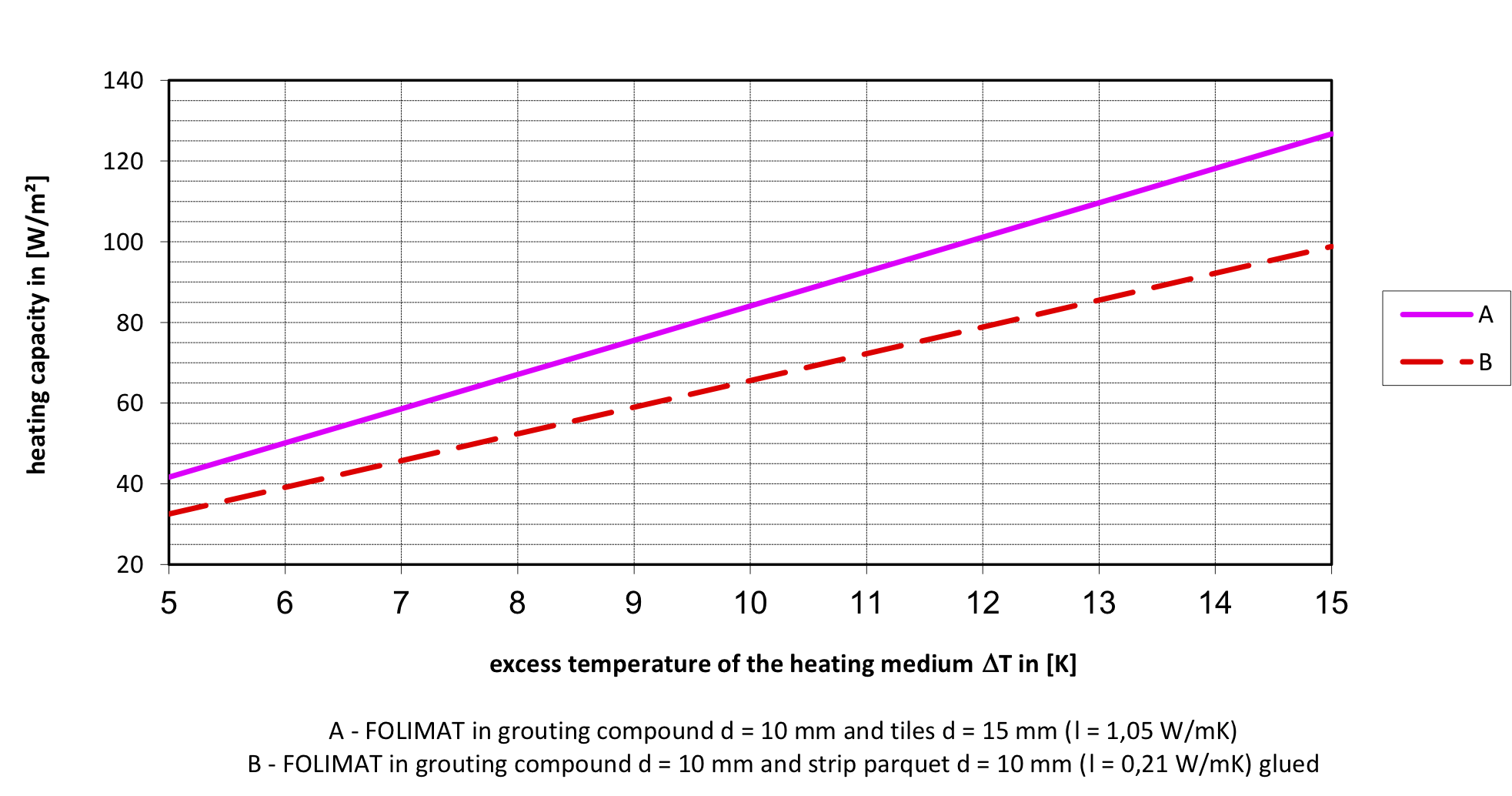

performance diagram

HEATING CAPACITY WITH FOLIMAT FSB 20