system description

Design

Clina OPTIPANEL 15 is a prefabricated gypsum board panel with an integrated capillary tube mat. The OPTIPANEL 15 are screwed onto the profiles of a substructure. On the visible side there is a seamless gypsum board ceiling for the removal or supply of sensitive heat loads. The water circulates noiselessly in the capillary tube mats and regulates the room temperature to a large extent via radiation, partly also via convection.

Gypsum board panel & Capillary tube mat

The OPTIPANEL 15 consists of a 12,5 mm unperforated gypsum board panel and the Clina capillary tube mat OPTIMAT GB 15.

Length & Width & Panel thickness

Clina manufactures the OPTIPANEL 15 in the dimensions 2.000 x 625 mm or 2.000 x 1.250 mm (standard).

Other, project-specific dimensions can also be delivered. The panel thickness is 12,5 mm.

Hydraulic connection

The connections between the OPTIPANEL 15 and the connection to the supply and return lines/ceiling sub-distributors are made on site using a proven push-lock system with flexible hoses. Pipes and sub-distributors are housed in the ceiling cavity.

Of course, the ceiling cavity can be used for other installations.

Mounting

The prefabricated OPTIPANEL 15 are screwed onto the profiles of the substructure.

The screws are screwed in through holes drilled in the factory.

Processing

According to the common rules of drywall. Processing of inactive areas with 12,5 mm standard gypsum board panels.

Lamps & Ventilation

Openings have to be taken into account in the planning phase.

Regulation

The system can be regulated room-by-room.

Fields of application

Suitable for the modern interior design of rooms with special acoustic requirements, such as office buildings or public buildings, whether new construction or renovation.

structure

The prefabricated OPTIPANEL 15 are screwed onto the profiles of the substructure. The screws are screwed in through holes drilled in the factory.

The connections between the OPTIPANEL 15 and the connection to the supply and return lines/ceiling sub-distributors are made on site using a proven push-lock system with flexible hoses.

Pipes and sub-distributors are housed in the ceiling cavity.

Of course, the cavity can be used for other installations.

prefabricated product

In an unperforated 12,5 mm gypsum board panel, parallel slots are milled on the back at a distance of 15 mm.

The capillaries of the capillary tube mat OPTIMAT GB 15, consisting of a round mat distributor pipe (20 x 2,0 mm) and capillary tubes (4,3 x 0,8 mm), are inserted into these slots.

The distance between the capillary tubes (centre-to-centre distance) is 15 mm.

The OPTIPANEL 15 is covered with a full-surface cover paper on the back.

advantages

Cooling and heating with one system

In most buildings, the heat requirement to be covered is so low due to the well-insulated building envelope that capillary tube mats integrated invisibly in the gypsum board ceiling not only provide excellent cooling in summer, but can also be used to heat very comfortably and energy-efficient in the cold season.

High degree of prefabrication

Factory prefabrication ensures quality, function and thermal performance.

Easy retrofitting

Can be screwed onto an existing substructure. The hydraulic connection is made in the ceiling cavity.

Activation does not increase the ceiling load.

Quick and easy installation

The hydraulic connection is made using a proven push-lock system.

This design can be installed completely in the drywall work, which ensures a smooth process on the construction site.

Individual room control

The temperature can be regulated room-by-room.

values

|

HEATING CAPACITY (ceiling) according to DIN EN 14037/5 |

COOLING CAPACITY (ceiling) according to DIN EN 14240 |

ACOUSTICS (ceiling) |

|

91,0 W/m² 77,3 W/m² |

74,4 W/m² 63,2 W/m² |

perforated variant see |

|

INSTALLATION HEIGHT: |

SYSTEM WEIGHT: |

PRESSURE STAGE: PN 10 |

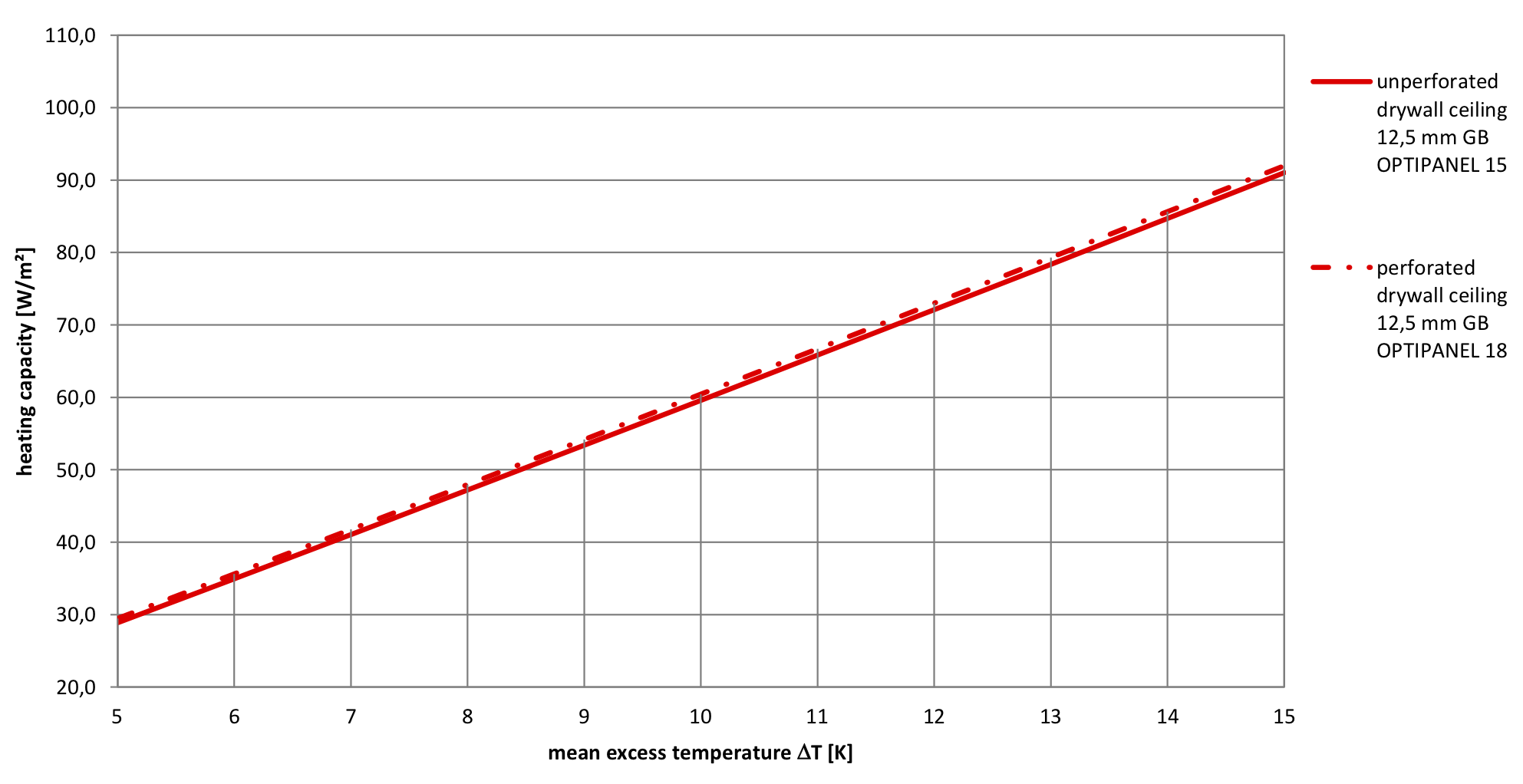

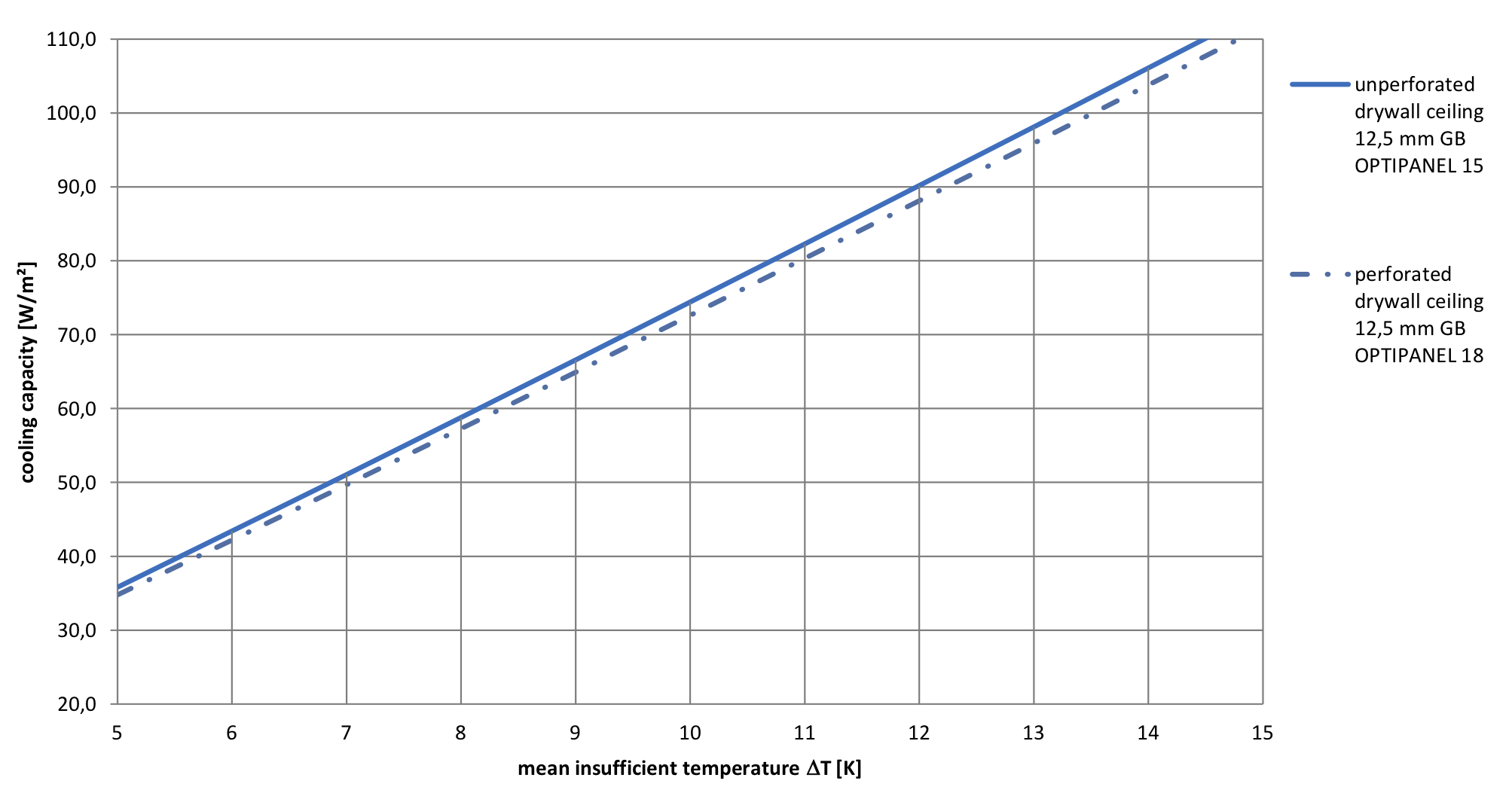

performance diagrams

SPECIFIC COOLING CAPACITY ACC. TO DIN EN 14240

SPECIFIC HEATING CAPACITY ACC. TO DIN EN 14240 / 14037-5 (DRAFT)